Customization and Design Flexibility

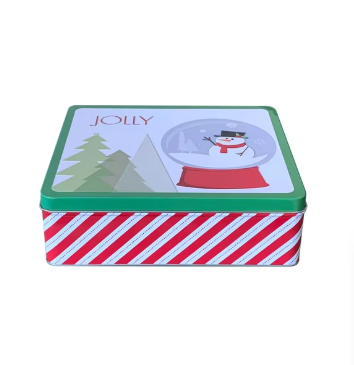

Tin boxes manufacturers excel in providing tailored solutions that precisely match customer specifications. Their design capabilities include advanced CAD/CAM systems for accurate prototyping and visualization of custom designs before production begins. The flexibility of their manufacturing processes accommodates various sizes, shapes, and decorative elements, enabling unique brand expressions through packaging. These manufacturers offer comprehensive finishing options, including specialty coatings, embossing, debossing, and high-quality printing techniques that enhance product aesthetics and functionality. Their expertise in material selection ensures that each custom solution optimally balances durability, cost-effectiveness, and aesthetic appeal.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY LA

LA