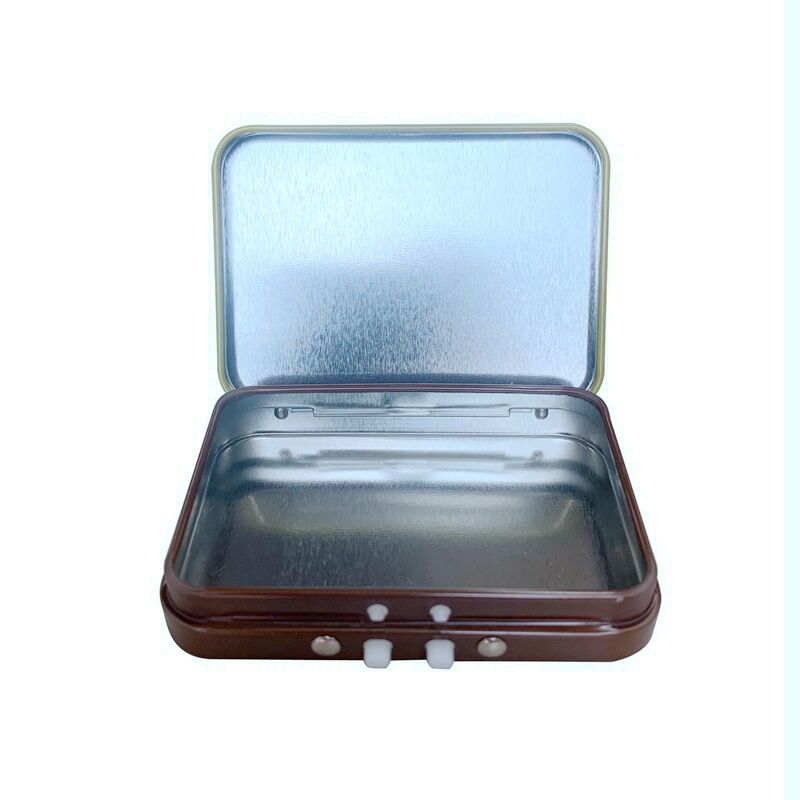

tinplate cans

Tinplate cans represent a cornerstone in modern packaging solutions, combining durability, functionality, and sustainability. These containers are manufactured using thin steel sheets coated with a microscopic layer of tin, creating a robust and versatile packaging material. The primary function of tinplate cans lies in their exceptional ability to preserve and protect various contents, from food products to industrial materials. The technological features include a hermetic sealing system that prevents contamination and maintains product freshness, while the tin coating provides superior corrosion resistance and ensures product safety. The manufacturing process involves advanced coating technologies and precise engineering to achieve consistent quality and reliability. These cans are designed with multiple layers of protection, including interior lacquers that prevent direct contact between the contents and the metal surface. In industrial applications, tinplate cans serve various sectors, including food and beverage packaging, chemical storage, and aerosol containers. Their stackability and uniform shape optimize storage and transportation efficiency, while their recyclability aligns with modern sustainability requirements. The standardized production processes ensure consistent quality and compatibility with automated filling lines, making them ideal for large-scale manufacturing operations.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY LA

LA