The medical and pharmaceutical industries demand packaging solutions that prioritize safety, sterility, and product integrity. Among the various packaging options available, the aluminum tin has emerged as a preferred choice for numerous medical applications. These versatile containers offer exceptional barrier properties, chemical resistance, and tamper-evident features that make them indispensable in healthcare settings. Understanding the specific role of aluminum tin packaging in medical environments reveals why these containers continue to gain prominence across pharmaceutical manufacturing, medical device storage, and healthcare facilities worldwide.

Material Properties and Safety Standards

Barrier Protection and Chemical Resistance

The aluminum tin provides exceptional barrier protection against moisture, oxygen, and light penetration, making it ideal for sensitive pharmaceutical compounds. The non-porous nature of aluminum creates an impermeable seal that maintains product stability and extends shelf life. This barrier functionality proves crucial for medications that degrade when exposed to environmental factors, ensuring therapeutic efficacy remains intact throughout the storage period.

Chemical resistance represents another critical advantage of aluminum tin packaging in medical applications. The inert surface of aluminum prevents unwanted chemical interactions with stored pharmaceuticals, maintaining drug purity and potency. This resistance extends to various cleaning agents and sterilization processes commonly used in medical facilities, allowing for proper sanitization without compromising container integrity.

Regulatory Compliance and Quality Assurance

Medical-grade aluminum tin containers must meet stringent regulatory requirements established by agencies such as the FDA and European Medicines Agency. These standards encompass material composition, manufacturing processes, and quality control measures that ensure patient safety. Compliance with Good Manufacturing Practices (GMP) guidelines becomes essential for pharmaceutical companies utilizing aluminum tin packaging solutions.

Traceability and documentation requirements further emphasize the importance of quality assurance in aluminum tin manufacturing. Each container must maintain detailed records regarding material sourcing, production dates, and quality testing results. This comprehensive documentation supports regulatory audits and helps identify potential issues before they impact patient safety or product efficacy.

Applications in Pharmaceutical Manufacturing

Drug Storage and Distribution

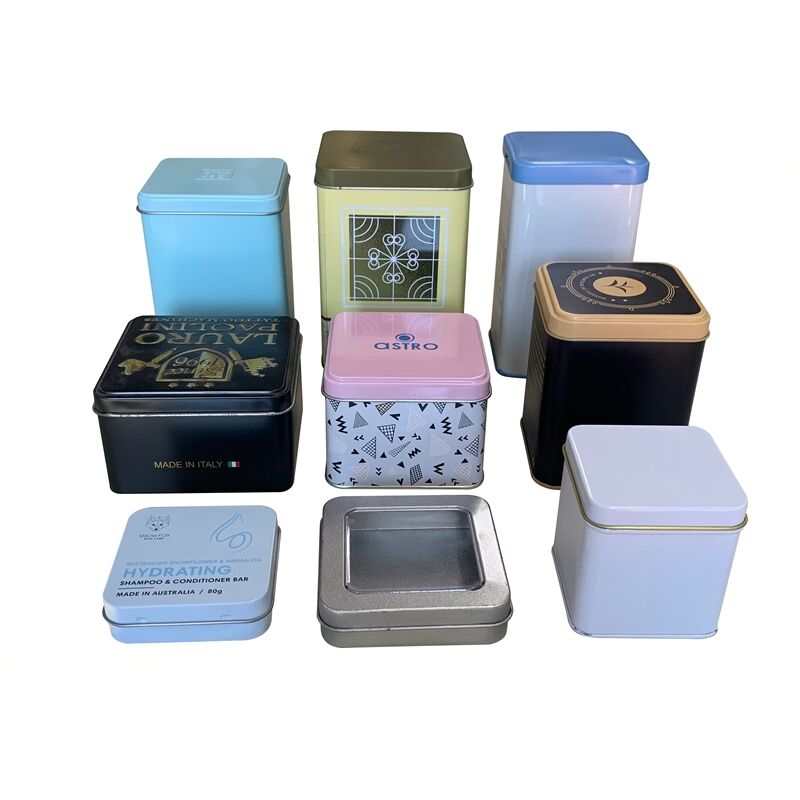

Pharmaceutical manufacturers rely on aluminum tin containers for storing various drug formulations, including tablets, capsules, and powdered medications. The secure closure system prevents contamination while maintaining product integrity during transportation and storage. These containers accommodate different batch sizes and facilitate efficient inventory management within manufacturing facilities.

Distribution networks benefit from the durability and stackability of aluminum tin packaging, reducing shipping costs and minimizing damage during transit. The lightweight nature of aluminum compared to glass alternatives decreases transportation expenses while maintaining equivalent protection levels. This cost-effectiveness makes aluminum tin solutions attractive for both domestic and international pharmaceutical distribution.

Clinical Trial Packaging

Clinical trials require specialized packaging that ensures blinding, dosage accuracy, and patient compliance tracking. The aluminum tin provides excellent customization options for clinical trial applications, including unique identification codes, tamper-evident seals, and patient instruction panels. These features support rigorous clinical protocols while maintaining participant safety.

Temperature stability during clinical trials becomes crucial for maintaining drug efficacy and ensuring accurate study results. Aluminum tin containers offer consistent thermal properties that help maintain stable internal temperatures during storage and transportation. This stability proves particularly important for temperature-sensitive biologics and experimental compounds used in clinical research.

Medical Device and Equipment Storage

Sterile Instrument Packaging

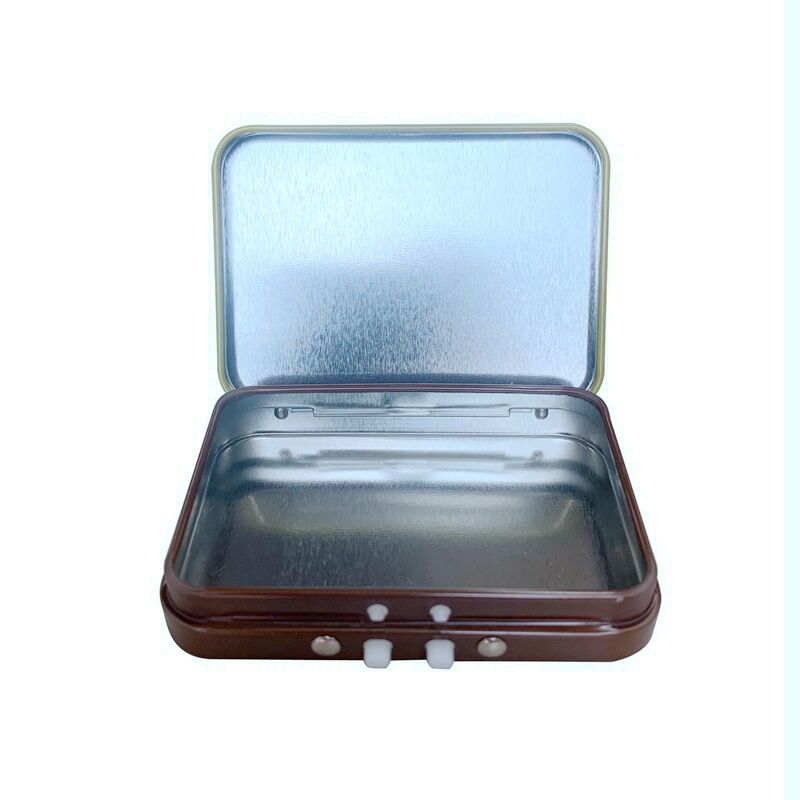

Medical facilities utilize aluminum tin containers for storing sterile instruments and small medical devices. The hermetic seal capabilities ensure sterility maintenance over extended periods, reducing the need for frequent re-sterilization cycles. This application proves particularly valuable in surgical suites, dental offices, and outpatient clinics where instrument availability directly impacts patient care efficiency.

Customizable compartments within aluminum tin containers allow for organized storage of different instrument types and sizes. This organization reduces preparation time for medical procedures and minimizes the risk of cross-contamination between different device categories. The clear labeling capabilities of aluminum surfaces further enhance inventory management and instrument tracking systems.

Emergency Medical Supplies

Emergency medical services and first aid applications benefit from the durability and portability of aluminum tin containers. These containers protect critical supplies from environmental damage while providing quick access during emergency situations. The lightweight design reduces the overall weight of emergency kits without compromising protection quality.

Long-term storage reliability makes aluminum tin containers ideal for emergency supply caches in hospitals, ambulances, and disaster response facilities. The corrosion-resistant properties ensure container integrity even under adverse storage conditions, maintaining supply readiness over extended periods. This reliability proves essential for emergency preparedness planning and disaster response capabilities.

Specialized Medical Applications

Radioactive Material Containment

Nuclear medicine departments utilize specialized aluminum tin containers for storing and transporting radioactive pharmaceuticals. The radiation shielding properties of aluminum provide additional safety measures while maintaining the sterility requirements of medical applications. These containers must meet both radiation safety standards and pharmaceutical packaging regulations simultaneously.

Disposal protocols for radioactive aluminum tin containers require careful consideration of both material composition and radiation decay periods. The recyclability of aluminum supports sustainable practices once radiation levels decrease to acceptable limits. This environmental consideration becomes increasingly important as healthcare facilities focus on reducing their ecological footprint.

Veterinary Medicine Applications

Veterinary pharmaceutical applications benefit from the same protective properties that make aluminum tin containers valuable in human medicine. Animal medications often require similar storage conditions and contamination prevention measures. The durability of aluminum tin packaging withstands the varied handling conditions common in veterinary practices and animal care facilities.

Species-specific dosing requirements can be accommodated through customized aluminum tin sizing and labeling systems. This customization helps prevent dosing errors and ensures appropriate medication administration across different animal species. The chemical resistance properties remain equally important for veterinary applications where medication stability directly impacts treatment outcomes.

Quality Control and Testing Procedures

Material Testing and Validation

Comprehensive testing protocols ensure aluminum tin containers meet medical industry standards before deployment. These tests include leak detection, seal integrity verification, and material composition analysis. Migration testing evaluates potential interaction between the aluminum tin surface and stored pharmaceutical products, ensuring no harmful substances transfer to medications.

Accelerated aging studies simulate long-term storage conditions to validate the stability of both the aluminum tin container and its contents. These studies help establish appropriate shelf life recommendations and storage condition requirements. Temperature cycling tests evaluate container performance under varying environmental conditions commonly encountered during distribution and storage.

Production Quality Assurance

Manufacturing quality assurance processes include real-time monitoring of aluminum tin production parameters such as wall thickness, surface finish, and dimensional accuracy. Statistical process control methods help identify potential quality issues before they impact large production batches. This proactive approach reduces waste and ensures consistent product quality across all aluminum tin containers.

Batch documentation and lot tracking systems provide complete traceability from raw aluminum materials through finished aluminum tin products. This documentation supports regulatory compliance requirements and enables rapid response to any quality issues that may arise. Customer notification systems ensure timely communication regarding any quality concerns or product recalls.

Environmental Considerations and Sustainability

Recycling and Lifecycle Management

The recyclability of aluminum tin containers supports sustainable practices in medical and pharmaceutical applications. Aluminum recycling requires significantly less energy compared to primary aluminum production, reducing the overall environmental impact of packaging solutions. Healthcare facilities can implement aluminum tin recycling programs that complement their broader sustainability initiatives.

Lifecycle assessments evaluate the environmental impact of aluminum tin containers from raw material extraction through disposal or recycling. These assessments help healthcare organizations make informed decisions about packaging choices while balancing environmental considerations with patient safety requirements. The longevity and reusability potential of aluminum tin containers contribute to reduced packaging waste generation.

Sustainable Manufacturing Practices

Aluminum tin manufacturers increasingly adopt sustainable production methods that minimize energy consumption and reduce environmental emissions. These practices include implementing renewable energy sources, optimizing production efficiency, and reducing material waste during manufacturing processes. Sustainable manufacturing aligns with the healthcare industry's growing focus on environmental responsibility.

Supply chain sustainability extends beyond manufacturing to include transportation optimization and packaging material sourcing. Local aluminum tin suppliers can reduce transportation-related emissions while supporting regional economic development. This approach benefits both environmental goals and supply chain resilience for medical and pharmaceutical applications.

Future Innovations and Technology Integration

Smart Packaging Technologies

Emerging technologies integrate sensors and monitoring capabilities into aluminum tin packaging systems. These smart packaging solutions can track temperature, humidity, and tampering events throughout the product lifecycle. Real-time data collection supports improved quality assurance and supply chain visibility for pharmaceutical applications.

Connectivity features enable aluminum tin containers to communicate with inventory management systems and patient monitoring devices. This integration supports automated reordering processes and medication adherence tracking programs. The combination of traditional aluminum tin protection with modern technology capabilities creates enhanced packaging solutions for evolving healthcare needs.

Advanced Manufacturing Techniques

Precision manufacturing technologies enable the production of aluminum tin containers with increasingly tight tolerances and specialized features. Advanced forming techniques create complex geometries that optimize storage efficiency and user accessibility. These manufacturing improvements expand the potential applications for aluminum tin containers in medical and pharmaceutical settings.

Additive manufacturing technologies show promise for creating customized aluminum tin components and specialized closure systems. This customization capability supports personalized medicine applications and unique pharmaceutical formulation requirements. The flexibility of advanced manufacturing techniques enables rapid prototyping and small-batch production for specialized medical applications.

FAQ

What makes aluminum tin containers suitable for pharmaceutical storage

Aluminum tin containers provide exceptional barrier properties against moisture, oxygen, and light while offering chemical resistance that prevents interaction with pharmaceutical compounds. Their hermetic sealing capabilities maintain product sterility and stability, making them ideal for storing medications, medical devices, and pharmaceutical ingredients. The inert nature of aluminum ensures no contamination or degradation of stored products.

How do aluminum tin containers meet medical industry regulations

Medical-grade aluminum tin containers comply with FDA and international regulatory standards through strict manufacturing processes, material composition controls, and quality assurance protocols. They meet Good Manufacturing Practices guidelines and undergo rigorous testing for leak integrity, material migration, and sterility maintenance. Comprehensive documentation and traceability systems support regulatory compliance and audit requirements.

Can aluminum tin containers be recycled after medical use

Yes, aluminum tin containers can be recycled after proper cleaning and decontamination procedures, provided they haven't been exposed to hazardous materials or radioactive substances. The recycling process requires significantly less energy than producing new aluminum, supporting sustainability goals in healthcare facilities. However, containers used for certain medical applications may require specialized disposal methods according to local regulations.

What are the advantages of aluminum tin over other medical packaging materials

Aluminum tin containers offer superior barrier protection compared to plastic alternatives while being lighter and more durable than glass containers. They provide excellent chemical resistance, customizable sizing options, and tamper-evident features that enhance patient safety. The combination of protection, durability, and cost-effectiveness makes aluminum tin containers particularly attractive for pharmaceutical and medical device applications.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY LA

LA